Product Description

V2O5 Melting Furnace

The traditional process is to put the vanadium metavanadate (or ammonium polyvanadate) filter cake into the rotary kiln and gradually complete the drying and deamination process after a long time of heating.

The shortcomings are as follows:

1. The contents of rotary kiln are easy to stick to the cylinder wall and the lifting plate.

2. Rotating ammonium metavanadate in rotary kiln will form spheres. It is not conducive to ammonia removal and drying.

3. Oxygen is needed in the rotary kiln to prevent the production of low-cost vanadium. Dust is flying.

Three-step vanadium preparation process designed by our company

The three-step process, i.e. drying, deamination and melting, is completed in three stages.

1. First, vanadium cake is dried into powder by dryer (several seconds).

2. Deammonium is carried out in a fast deamination furnace (for a few seconds).

3. Melting in a smelting furnace (continuous outflow).

4. Formation of V2O5 thin films.

Detailed description:

I. Dryer

Flash drying method is adopted, that is, vanadium cake is fed into the dryer by feeder, and hot air is heated into the dryer. Under the action of mechanical dispersion, the vanadium cake is dried into powder quickly, and the powder ammonium vanadate is formed.

II. Deamination Furnace

The flash SD calciner is used to realize the rapid removal of ammonia. The dried vanadium powder is continuously fed into the ammonium removal furnace. Each particle is quickly mixed with hot air to absorb heat, and decomposed into V2O5 vanadium powder in continuous flow. After several seconds, the vanadium powder is decomposed into V2O5 vanadium powder (80%-85% of the ammonia gas is removed).

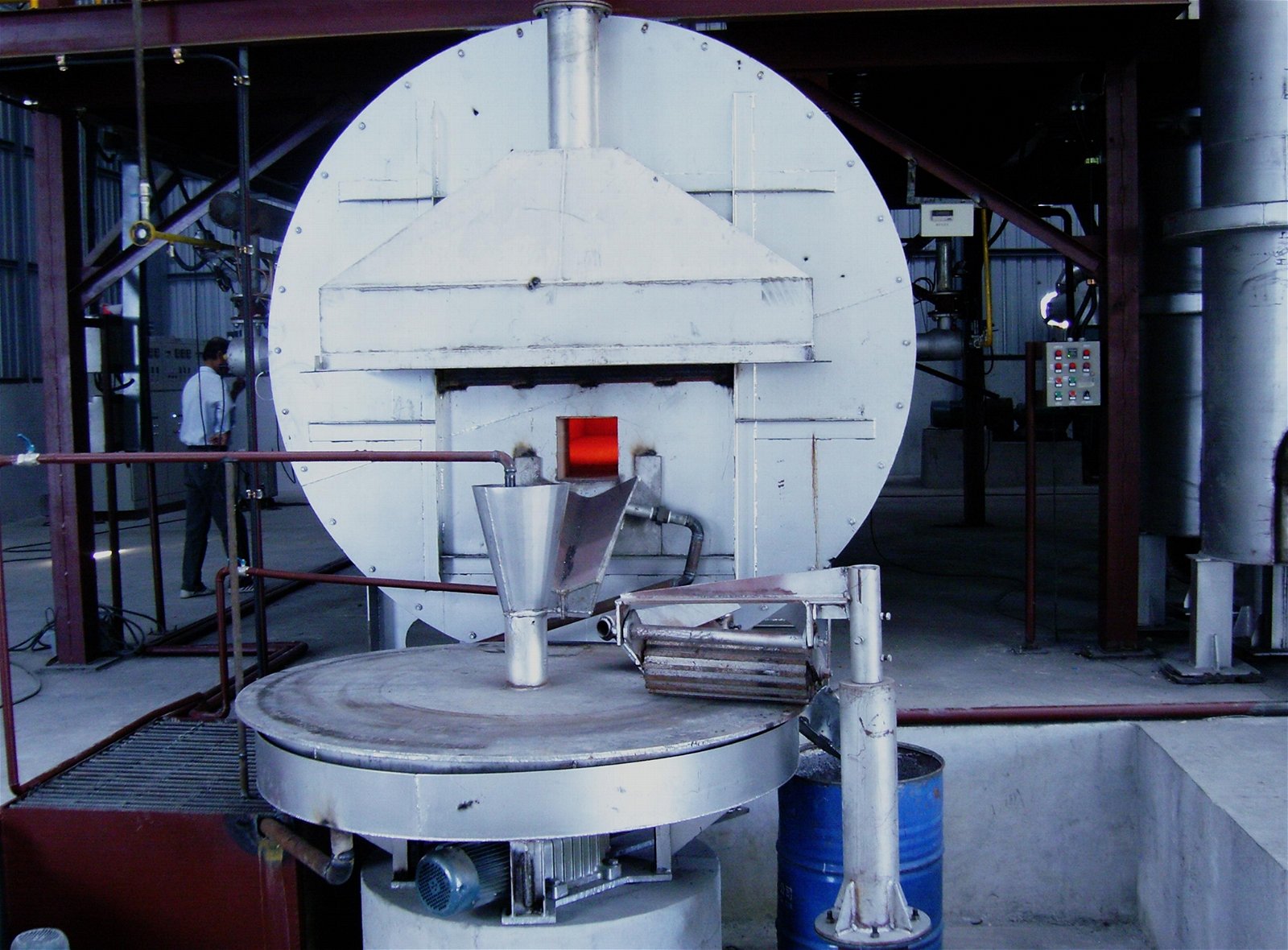

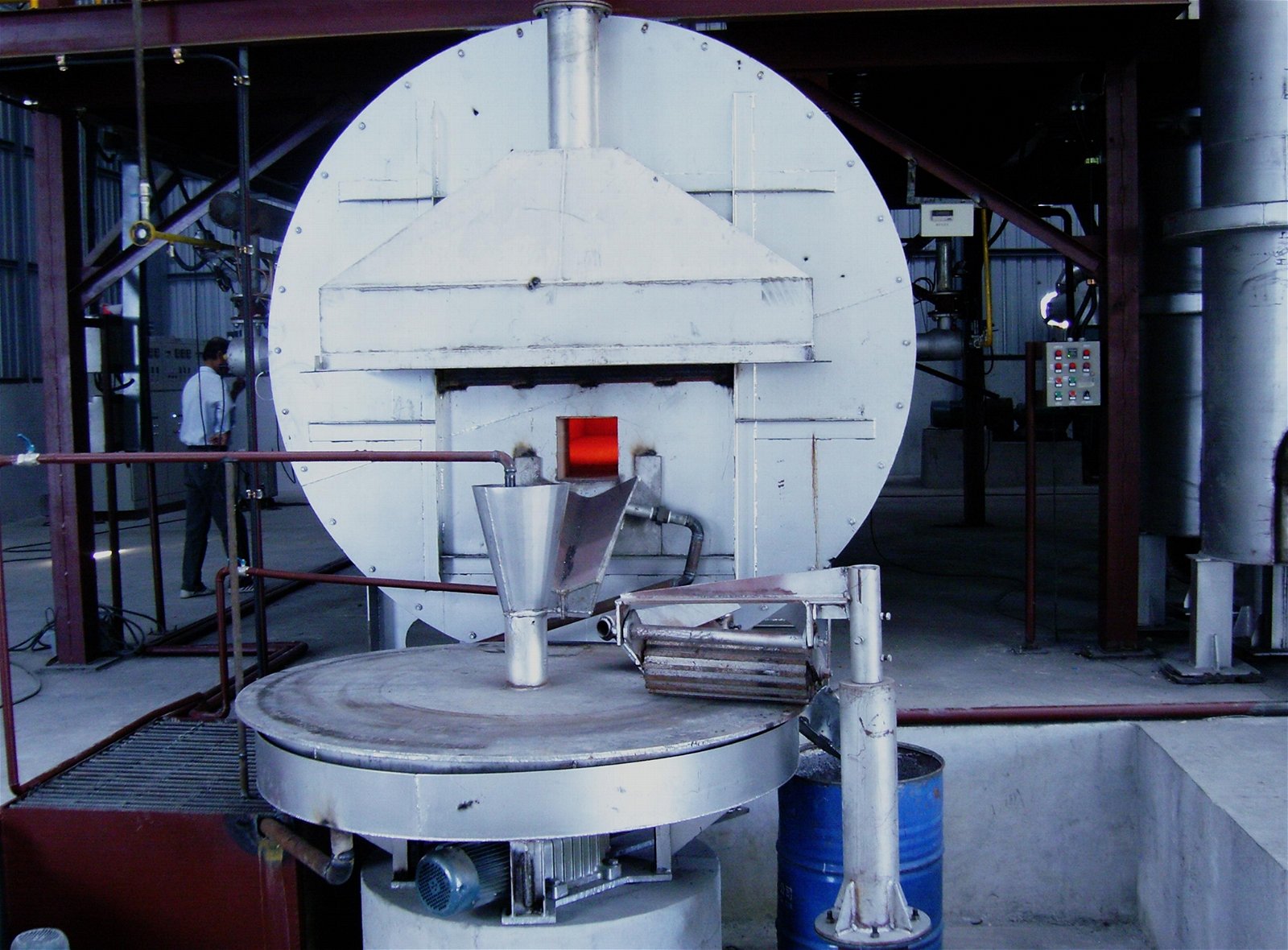

3. Melting Furnace

1. The melting speed is fast and the area is small.

2. Long service life.

3. Continuous production of v2o5.

4. The quality of V2O5 (Flake) is stable.

New three-step process

The three-step process can improve the efficiency of producing vanadium flakes. The hot air produced by flash smelting furnace can be used as a heat source for drying, that is, to effectively utilize heat and effectively recover gasified ammonia in air, which has remarkable economic benefits.

Moreover, the equipment operates under negative pressure and there is no dust leakage.

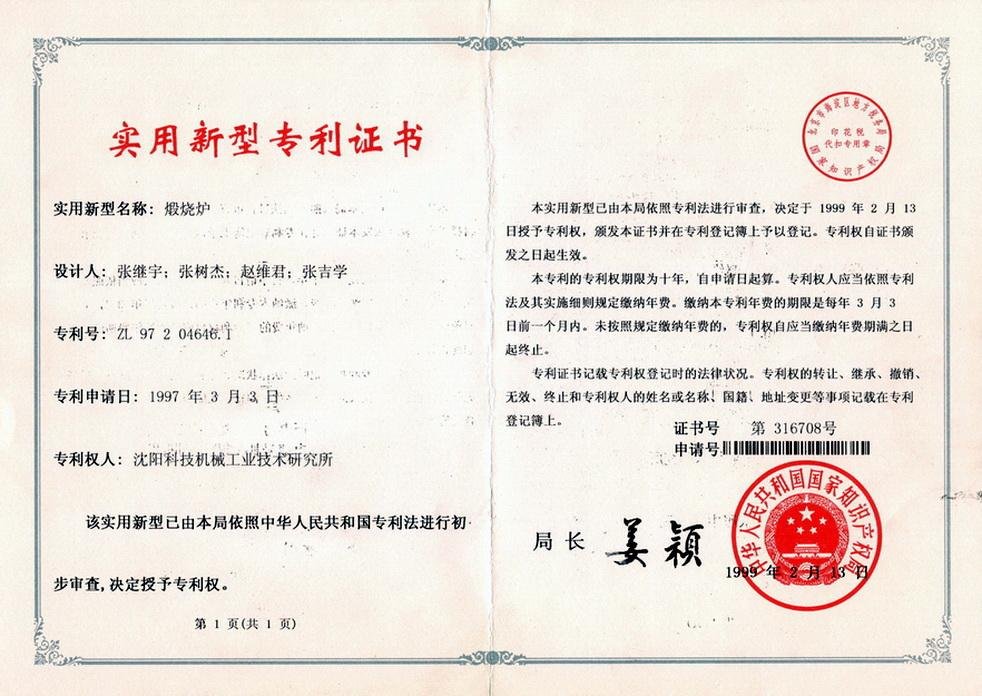

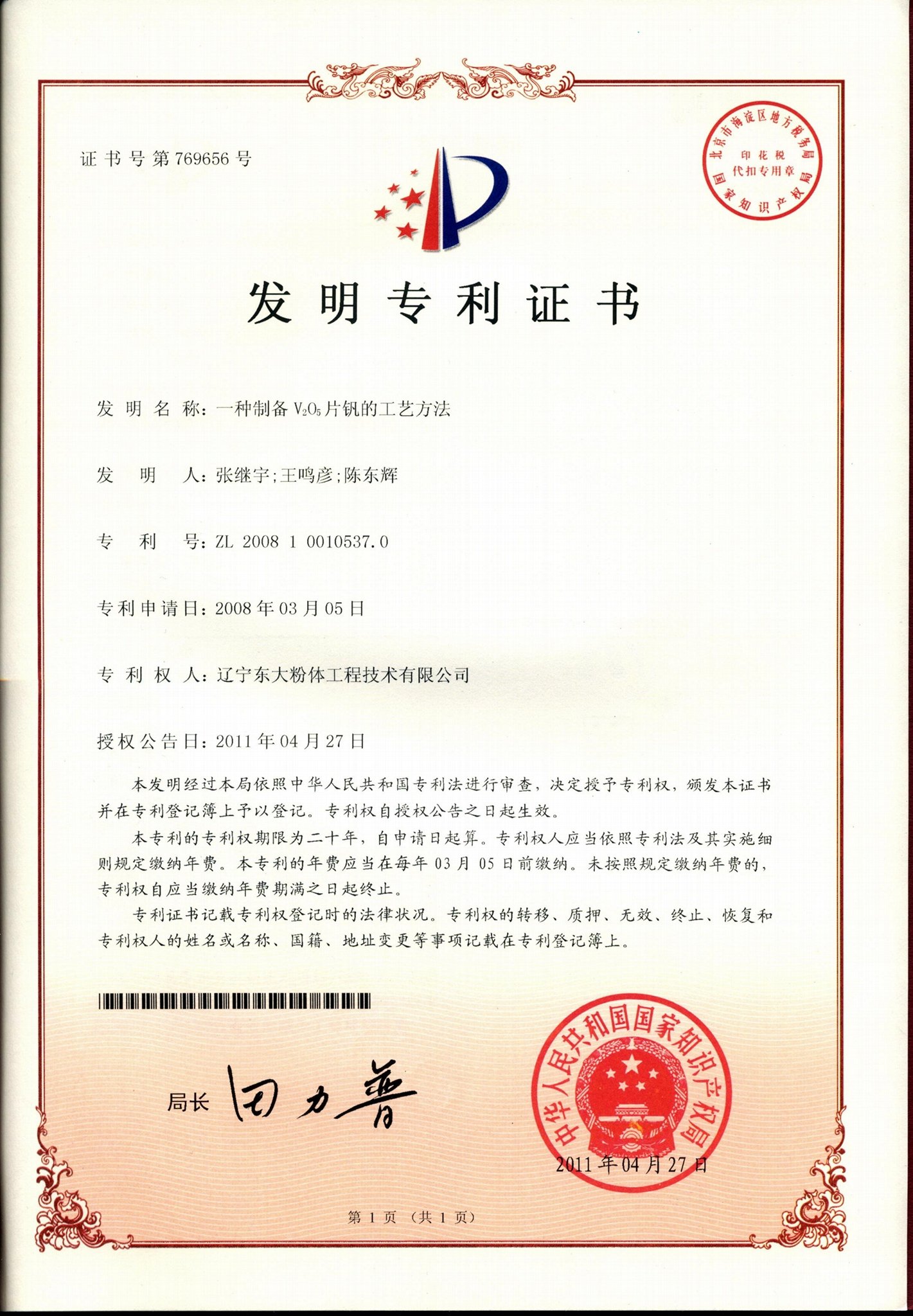

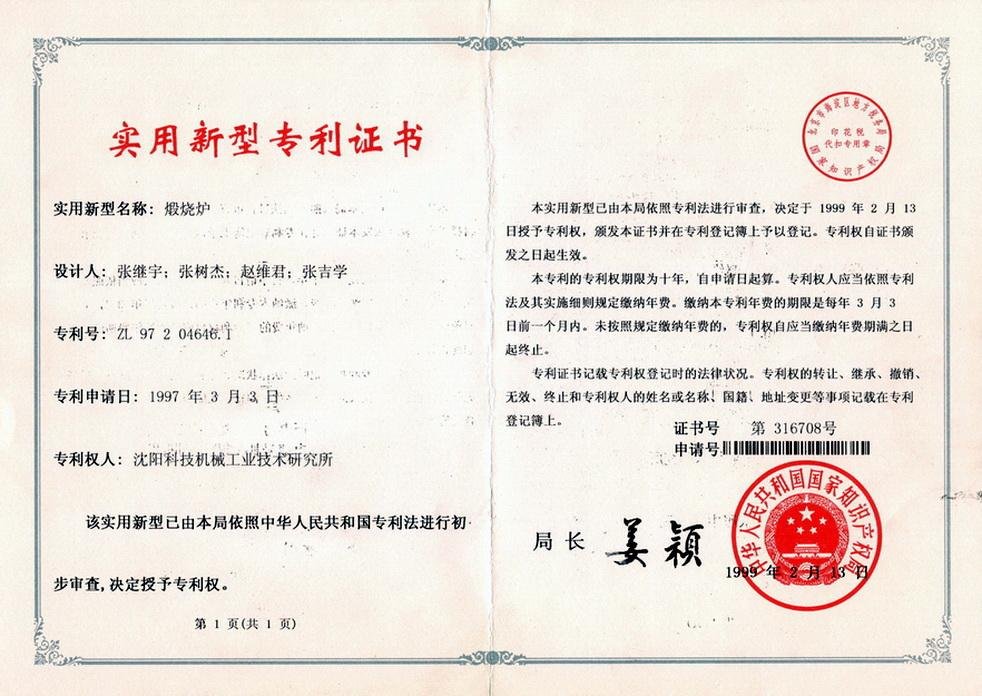

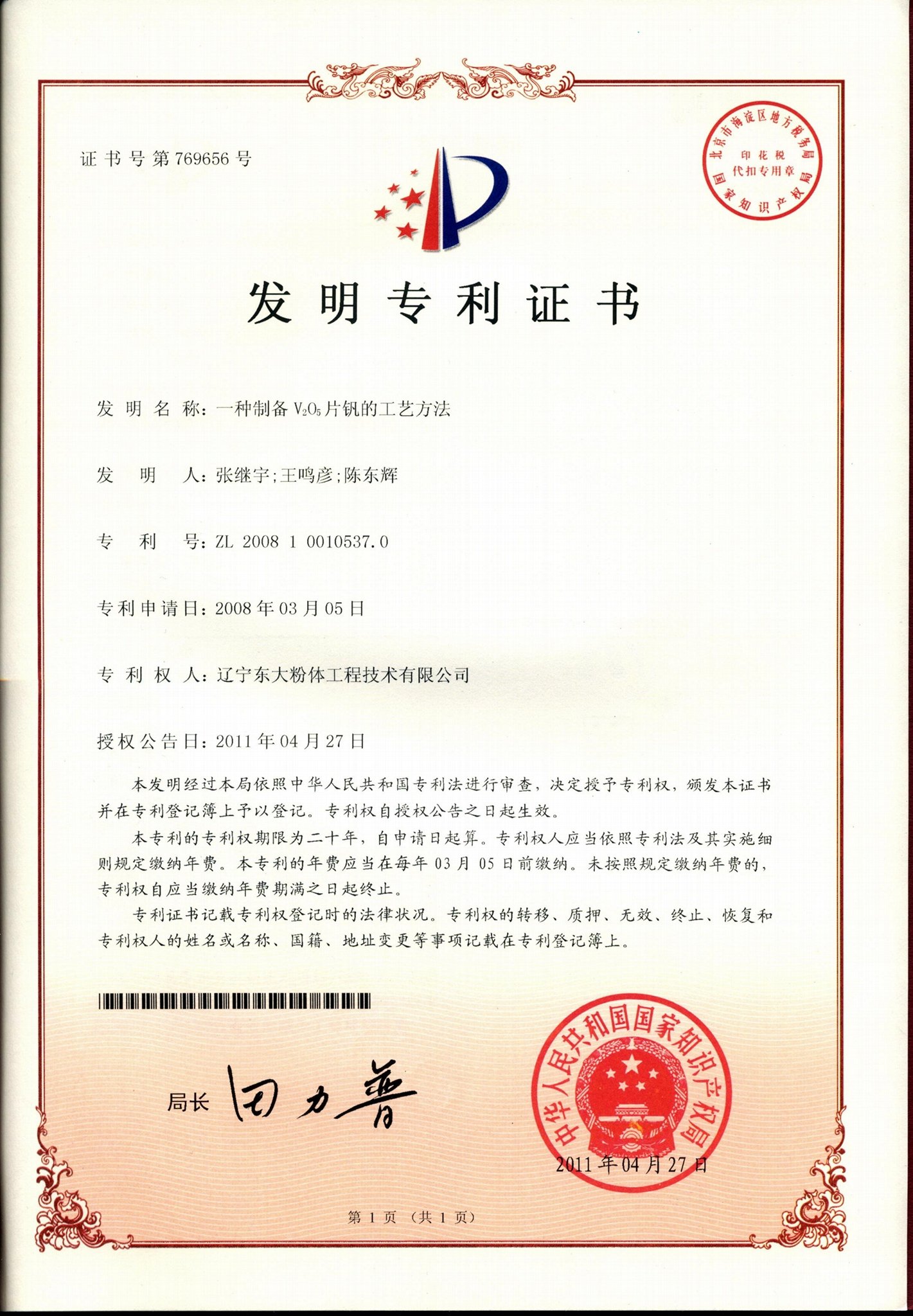

Our company's three-step drying, ammonia decomposition and rapid melting production of vanadium sheet (V2O5) has been patented.

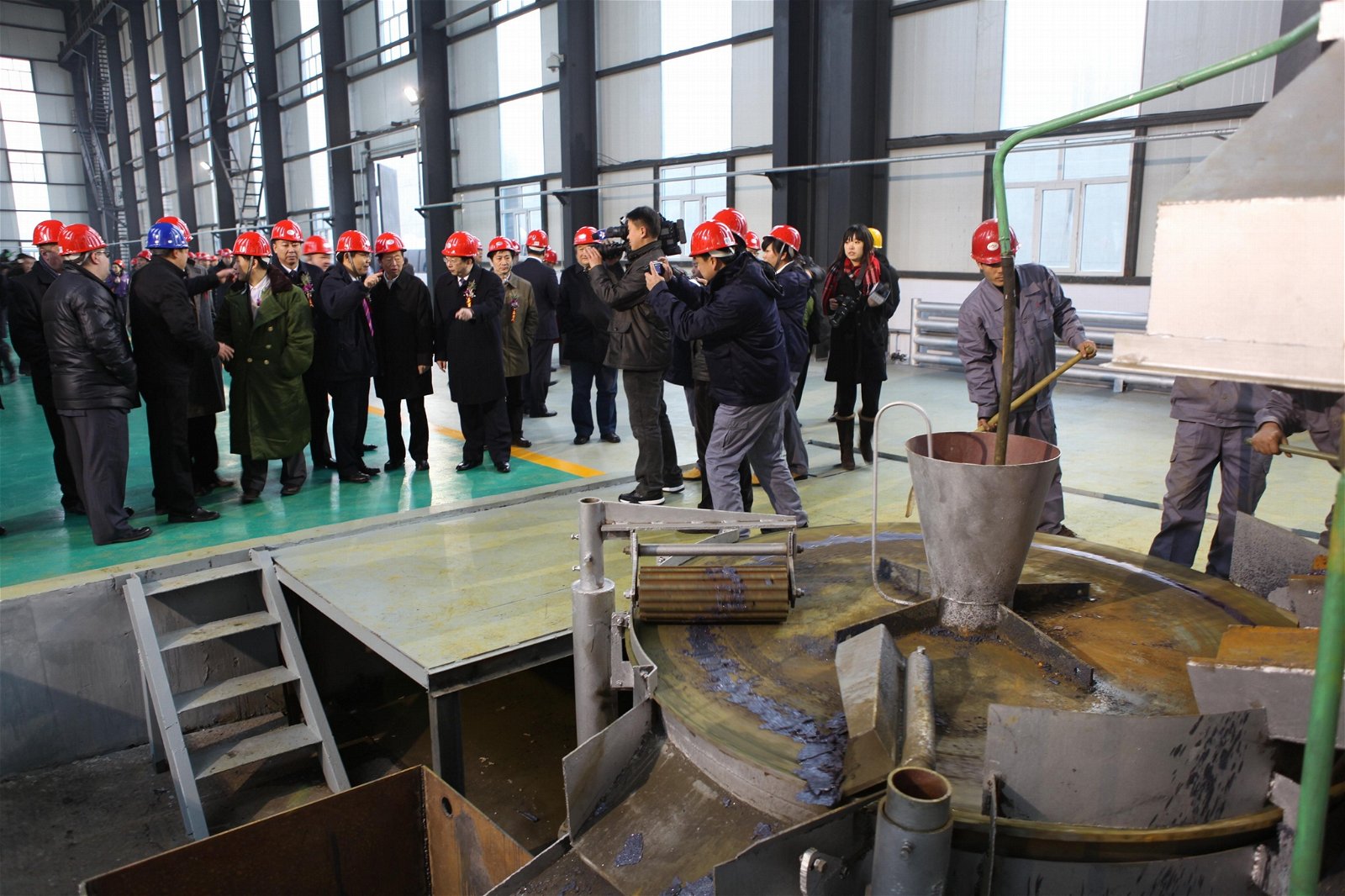

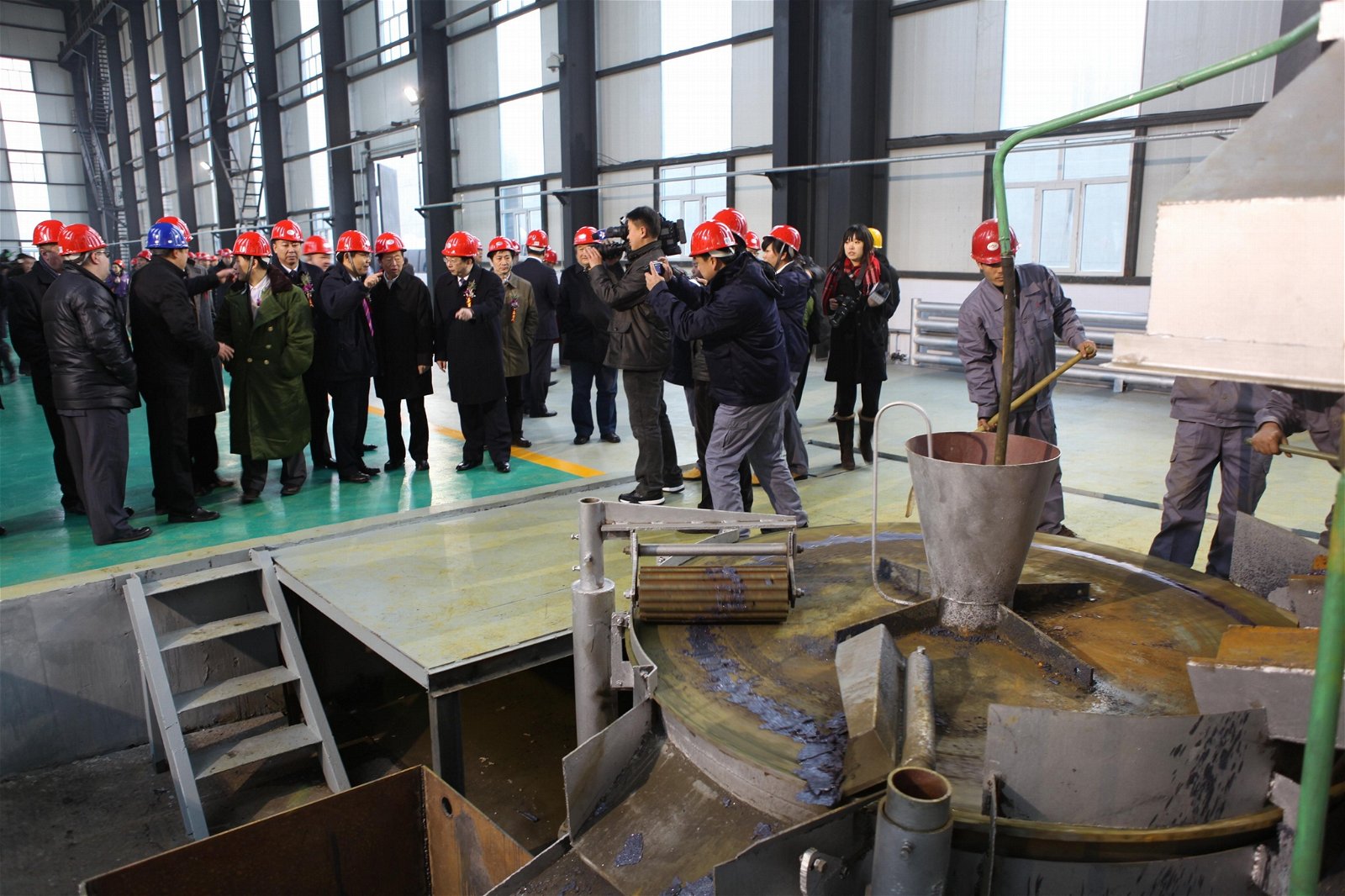

V2O5 equipment use enterprises:

1. Chengde Iron and Steel New Vanadium and Titanium Company (4000 tons/year)

2. Wuhan Jianlong Company (2000 tons/year)

3. Shaanxi Huayuan Mining Co., Ltd. (6000 tons/year)

4. Royang Ferroalloy Company of Thailand (1200 tons/year)

5. Shuangyashan Jianlong Company (Russian Joint Venture) (7000 tons/year)

6. Taiwan Huamao Co., Ltd. (1300 tons/year)

Product Image