Product Description

★ this plaster virtue forge to burn technology and equipment

Processing brief introduction

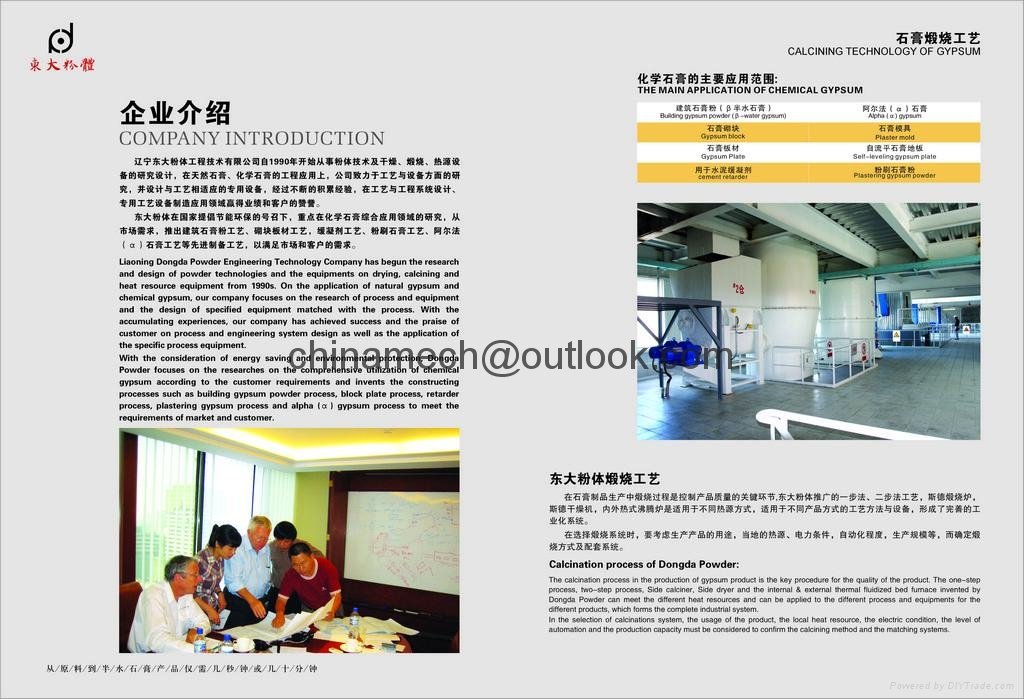

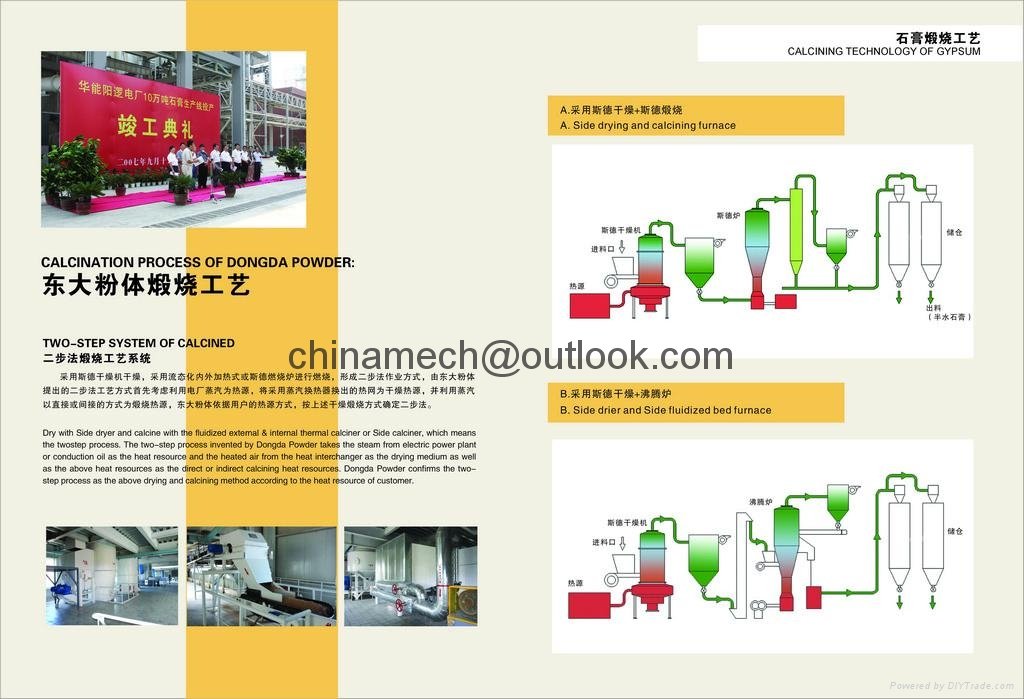

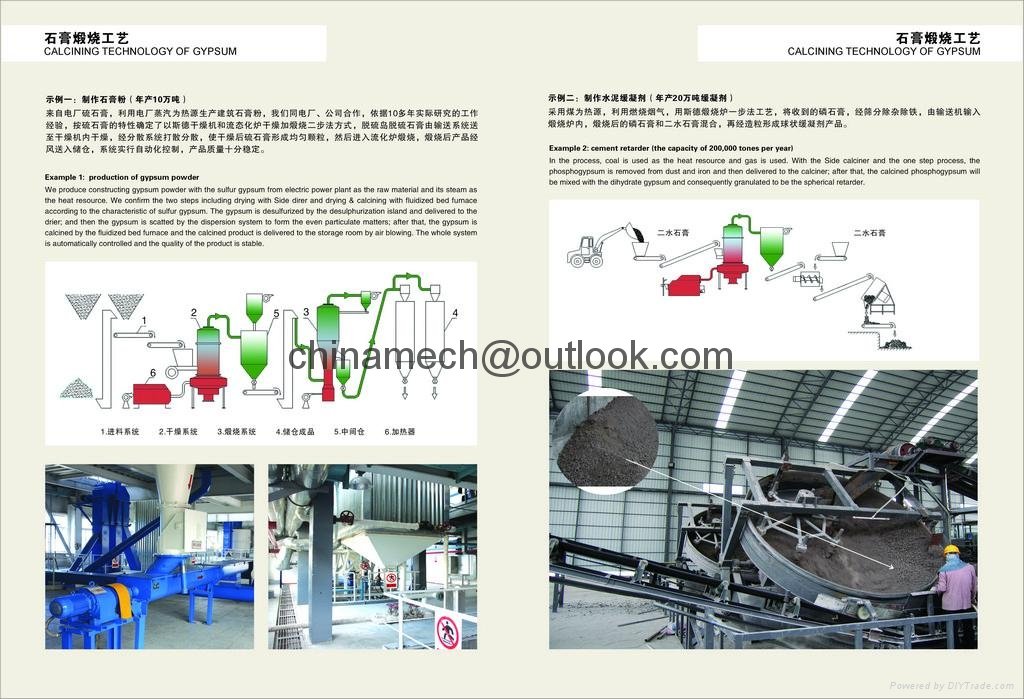

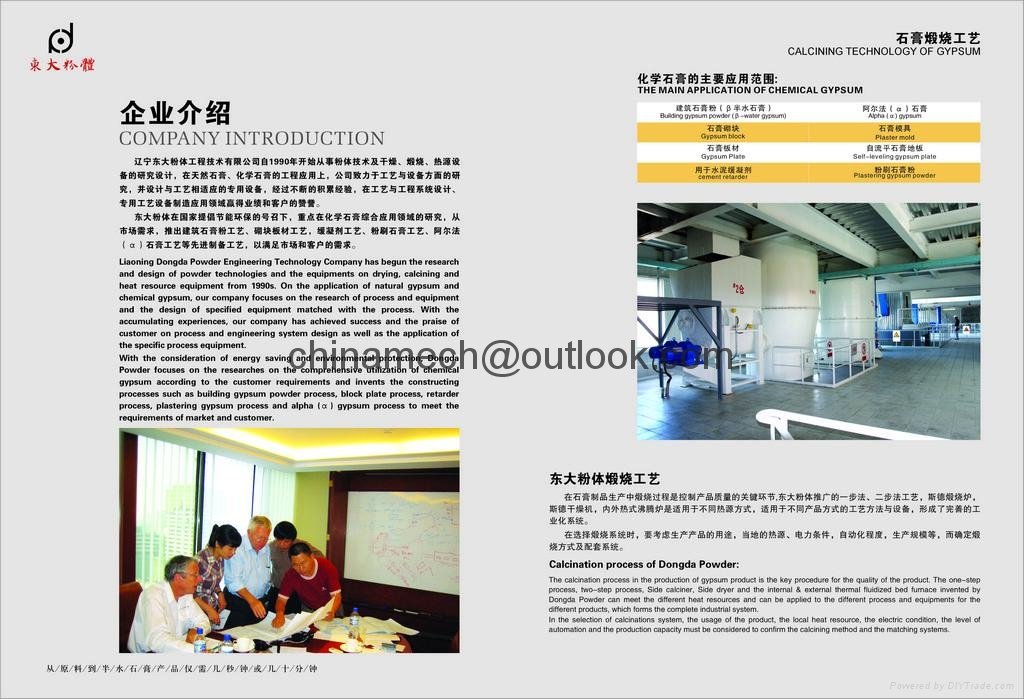

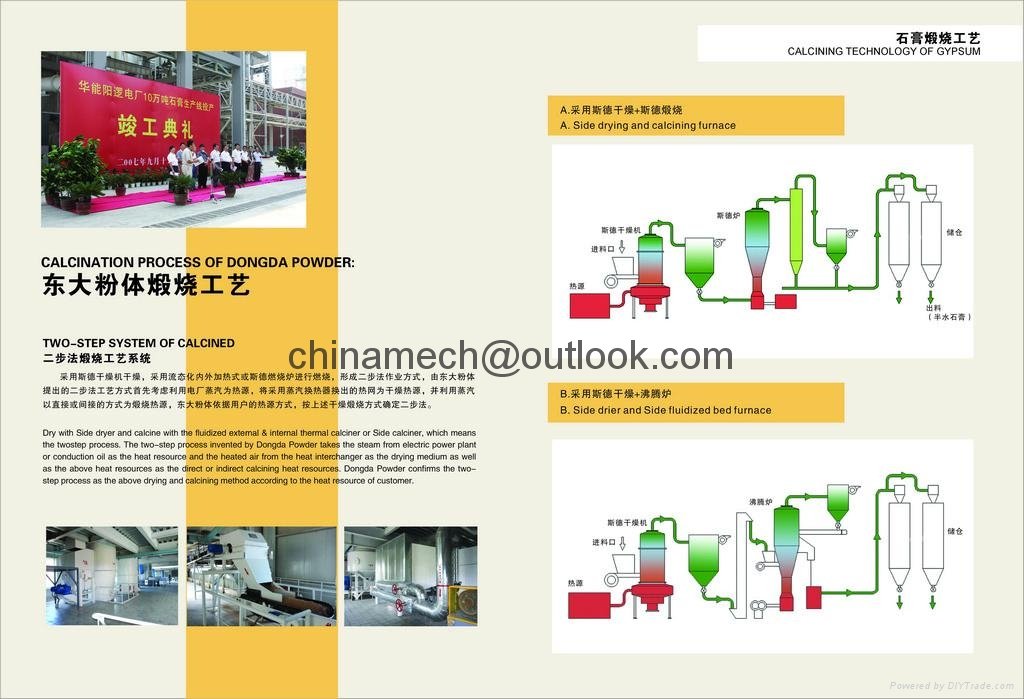

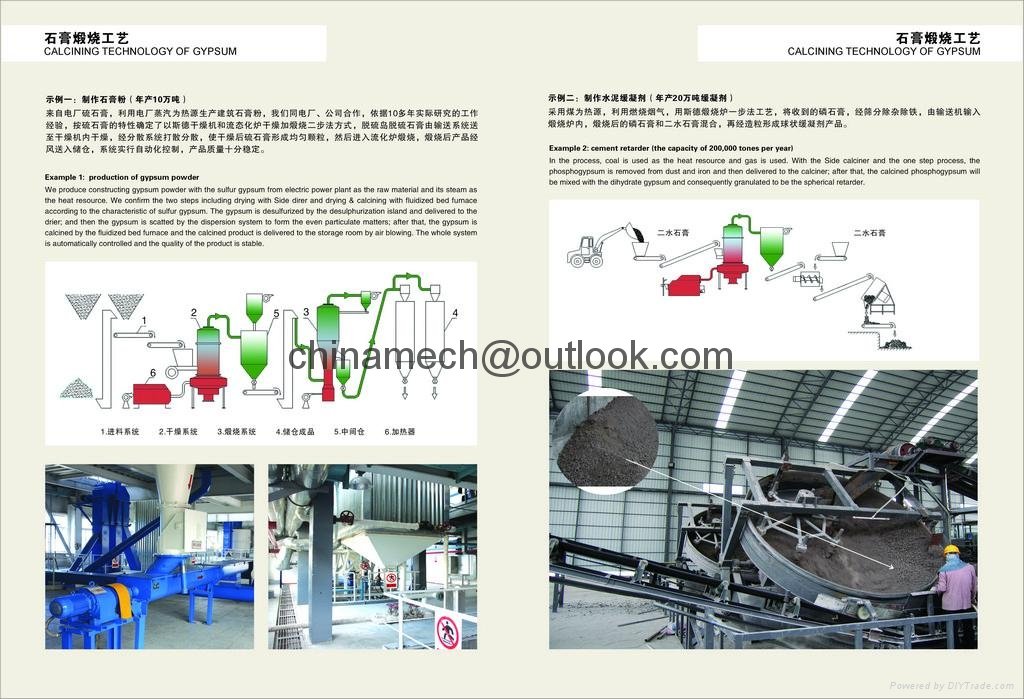

Sulphur plaster contain surface water to make half water plaster normally around 10%. According to the characteristic of sulphur plaster, our plenty of research and experiment of Scientists and Technologists are developed. Original dry forge to burn two step technology, walk as soon as improving technology. This virtue development forge to burn stove complete 4 road processes: 1. Dozen breaks up. 2. Dry. 3. Grade. 4. Forge to burn. First, take off surface water and then take off partially product water to get half water plaster, in production course, equipment will be dry and forge to burn minute as soon as step law process goes on , so not only, can get the half water plaster of higher function; Reduce the investment cost of equipment. With this virtue plaster development of this technology, forge to burn stove equipment in Beijing certain company repeatedly to run , as soon as practice proof adopts step law technology to forge the plaster powder burnt , every index exceeds national plaster standard.

Contain wet sulphur plaster from send material machine to send income to have dry scatter to grade to forge to burn this virtue of function to forge to burn stove , the hot air of coal fired enters this virtue to forge to burn the same stock appearance in stove to mix , making promptly continuous and dry become powder form stock and grade , and enter second road process development to forge to burn , go through 3 ~ 9 seconds of time forge firing is half water plaster. Forge to burn rear plaster powder process air-cooling , send the material of income storehouse after leveling. This virtue plaster forge to burn stove: Purpose engineering technology stands home, eastern big powder body project technical limited company( http :// dry. cebiz. cn) study development, sulphur , Lin wait for chemical plaster process to spin dry , development forge to burn , the plaster after leveling, can reach building plaster powder national standard. Can use make plaster block brick and plaster board etc..

This technology characteristic

1. According to sulphur plaster characteristic, determine reasonable dry forge to burn technology, can get high-class article with the half water plaster of this technology production, production plaster powder product can be directly used to produce the product such as face plate and block.

2. Equipment process is simple , continuous automation is produced , has big productivity , specific power consumption is low, it is short to forge to burn time, equipment operation is stabilized , and can realize automation control. Suit industrialization large-scale production , leak without dust , free from contamination , environmental protection reaches to mark. Can make acceptable building plaster powder efficiently using the local chemical plaster industrial production of waste residue, solve industrial waste residue to stack and pollute problem, it is treasure to change useless, economic and social benifit is notable. Equipment operation is stabilized and can realize automation control.

3. Product quality is stabilized , since dry and forge to burn synchronous step to go on , when forging to burn , can get steady product.

【】 this equipment have debuged operation in Beijing certain company, in hour, output reaches 8 tons.

Forge to burn rear plaster powder test result:

① fight to fold strength: 2.8 ~ 3.2 MPa ② congeal time: 7 ~ 8 minutes ③ congeal finally time: 15 ~ 18 minutes ④ smash , dry forge to burn to grade in forging to burn stove is completed. Some seconds of whole course general time clocks.

Produce per year quantity: The type such as twenty thousands tons, fifty thousands tons, one-hundred thousands tons and two-hundreds thousands tons.

Advantages︰

This technology characteristic

1. According to sulphur plaster characteristic, determine reasonable dry forge to burn technology, can get high-class article with the half water plaster of this technology production, production plaster powder product can be directly used to produce the product such as face plate and block.

2. Equipment process is simple , continuous automation is produced , has big productivity , specific power consumption is low, it is short to forge to burn time, equipment operation is stabilized , and can realize automation control. Suit industrialization large-scale production , leak without dust , free from contamination , environmental protection reaches to mark. Can make acceptable building plaster powder efficiently using the local chemical plaster industrial production of waste residue, solve industrial waste residue to stack and pollute problem, it is treasure to change useless, economic and social benifit is notable. Equipment operation is stabilized and can realize automation control.

3. Product quality is stabilized , since dry and forge to burn synchronous step to go on , when forging to burn , can get steady product.

Product Image